Description

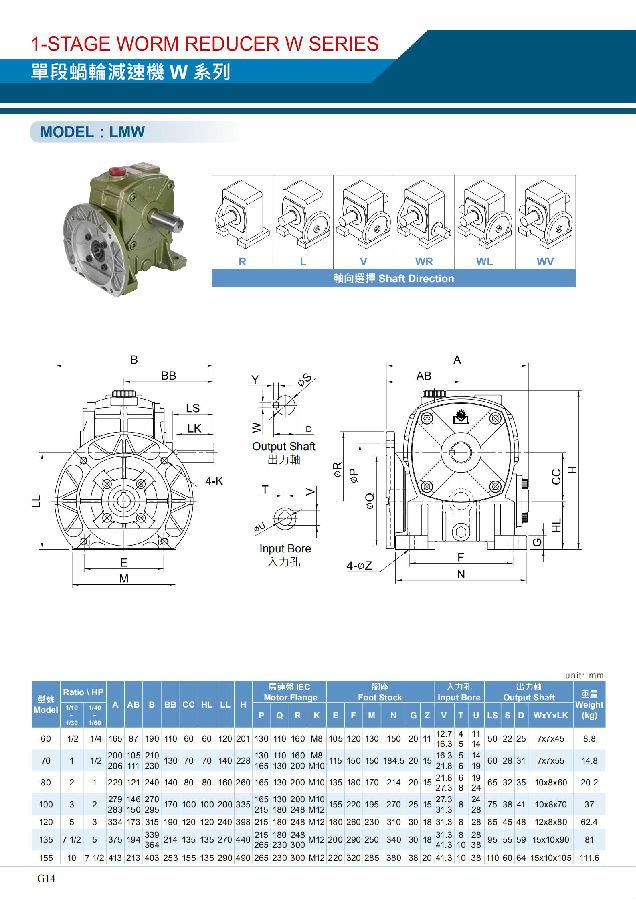

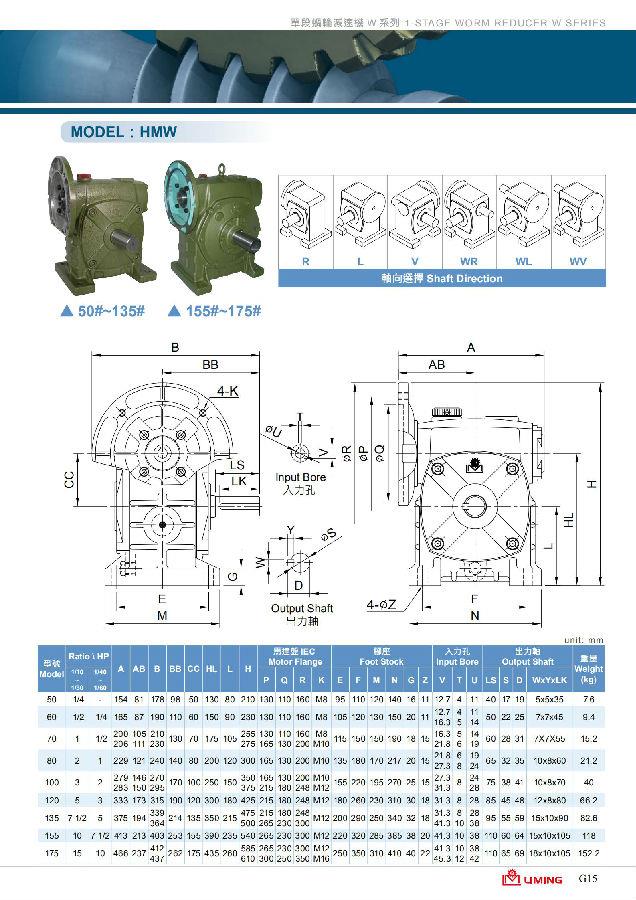

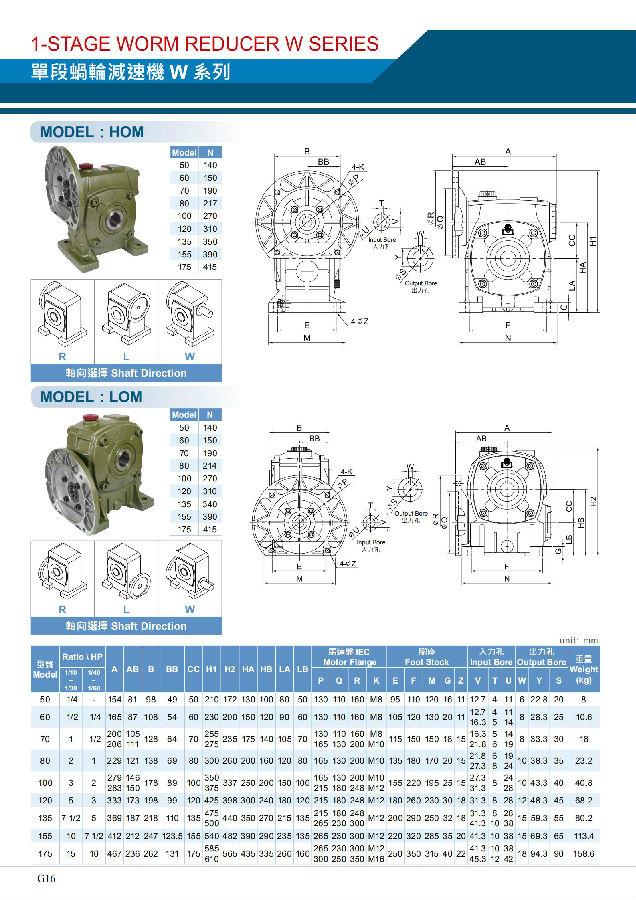

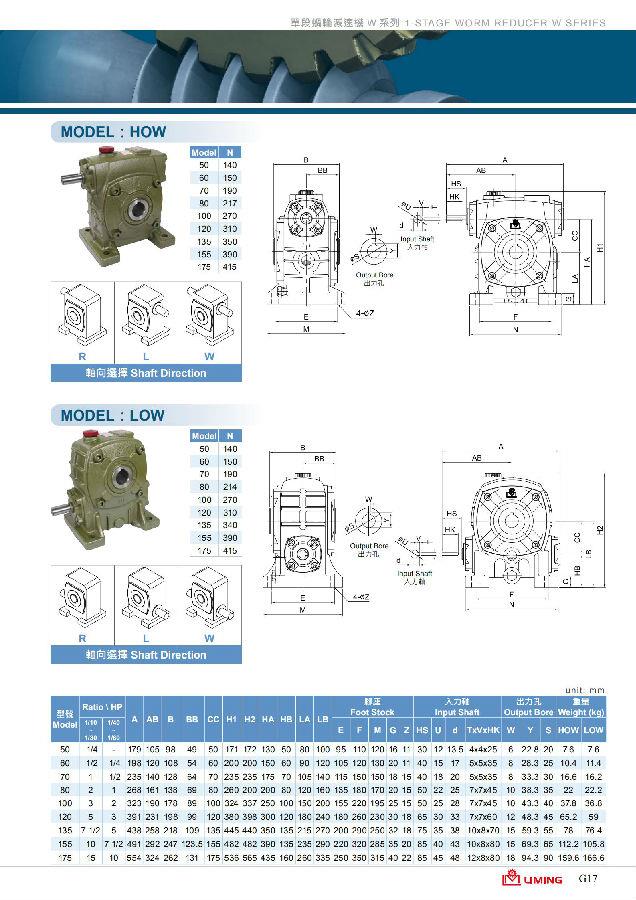

Generally speaking, if there is M in the model code, it is the direct-drive motor type, and the O is the output shaft, the hollow type has H, it is the two-stage worm gear reducer (worm wheel + worm gear) and G is Two-stage worm gear reducer (gear + worm gear)

Cast iron worm gear reducer

Liming reducerProduct advantages:

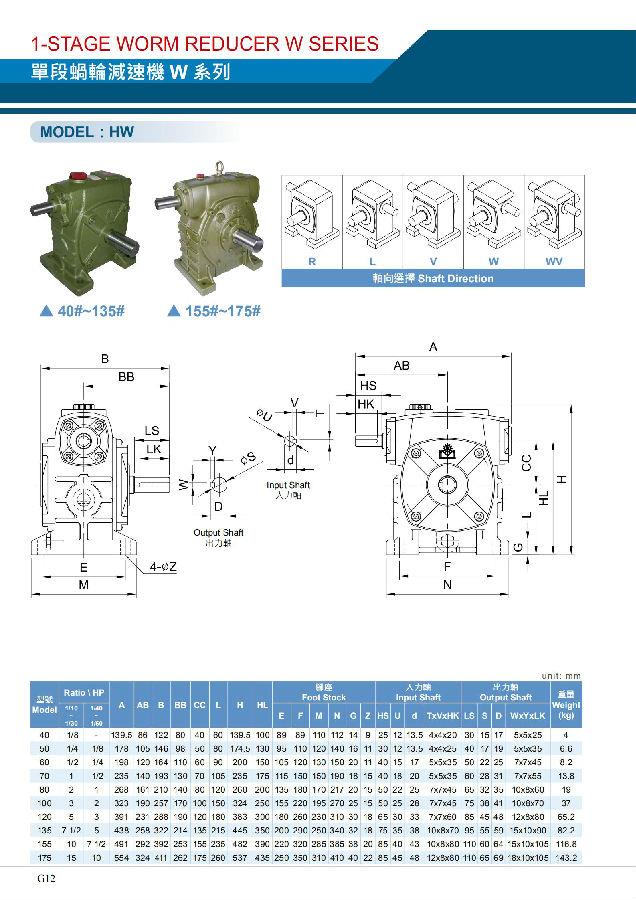

HW (basic type)

Output shaft: medium carbon steel S45C, precision machined and ground by CNC lathe.

Worm gear: aluminum bronze ALBC3& FC20, using special cutting tools for forming and computer-aided design, with low friction coefficient and long service life.

Output shaft cover: cast iron FC20 or cast aluminum AL, precision processed by CNC lathe.

Worm gear box: cast iron FC20, the body is cast in one piece, strong strength, beautiful appearance, good heat dissipation effect.

Worm: Medium carbon steel S45C or SCM21 precision gear hobbing machine, after heat treatment, the tooth profile is ground, so the tooth profile is correct, the tooth surface is smooth, and the operation efficiency is high without noise.

Right input shaft cover: cast iron FC20 or cast aluminum AL

Left input shaft cover cast iron FC20 or cast aluminum AL

It is distinguished according to different external transmission modes: Generally speaking, those with M in the model code are motor direct-coupled models, and O, for output shaft hollow models, and H, for two-stage worm gear reducers (worm gear {{ 0}}Worm gear) with G is a two-stage worm gear reducer (gear + worm gear)

Axial: The direction of rotation of the output shaft of the worm gear reducer depends on the direction of the worm screw. Except in special circumstances, all right-handed teeth are used. When the input axis is clockwise, the output axis is counterclockwise, but the rotation direction of the input axis and output axis of the two-stage worm gear reducer is the same direction. Worm gear reducer has many axial changes, please refer to&”select&”for axial direction in this catalog when using it. When not specified, the right axis (R) is used as the standard.

Features:

W series

HW: The input shaft is above the output shaft. Sprockets, pulleys, etc. can be installed conveniently and easily. However, when the model is large, it is difficult to supply lubricating oil. The model ranges from 40# to 175#.

HMW(MW): Same as HW, with additional motor disk and input hole, which can be directly connected to IEC size motors, fast and easy installation, models from 50# to 175#.

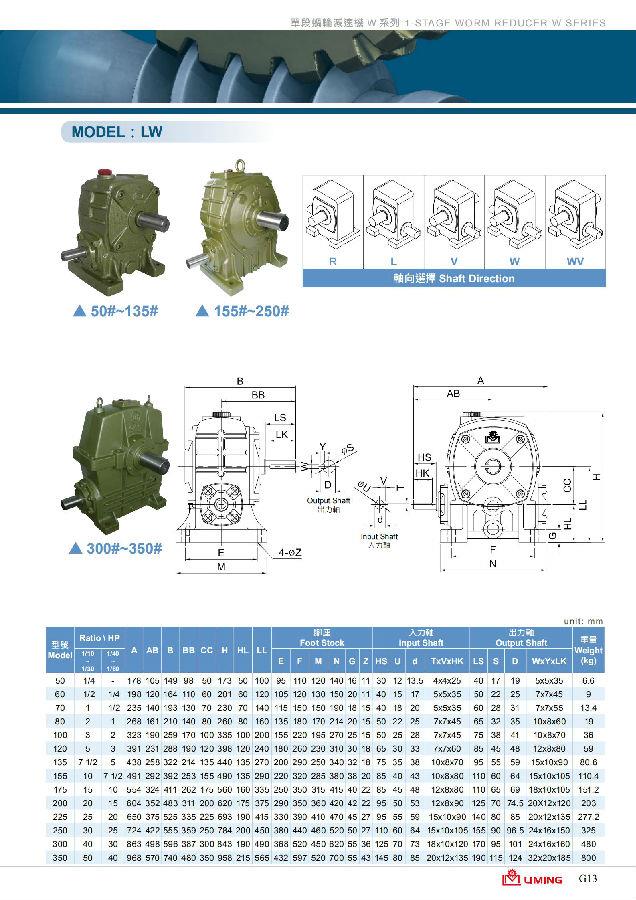

LW: The input shaft is under the output shaft, so that the input shaft is immersed in oil, which has a better lubrication effect and is suitable for higher torque transmission. Models range from 50# to 350#.

Speed ratio

General speed ratio of single-stage worm gear reducer: 1/10 1/15 1/20 1/30 1/40 1/50 1/60

Special speed ratio: 1/5 1/25 1/80

Two-stage worm gear reducer worm gear + worm gear: 1/100.1/3600 gear + worm gear: 1/80.1/300 worm gear reducer generally has a positive reduction ratio, but some models The table on the right of the non-positive reduction ratio is for reference only, please contact us if you need the correct reduction ratio.