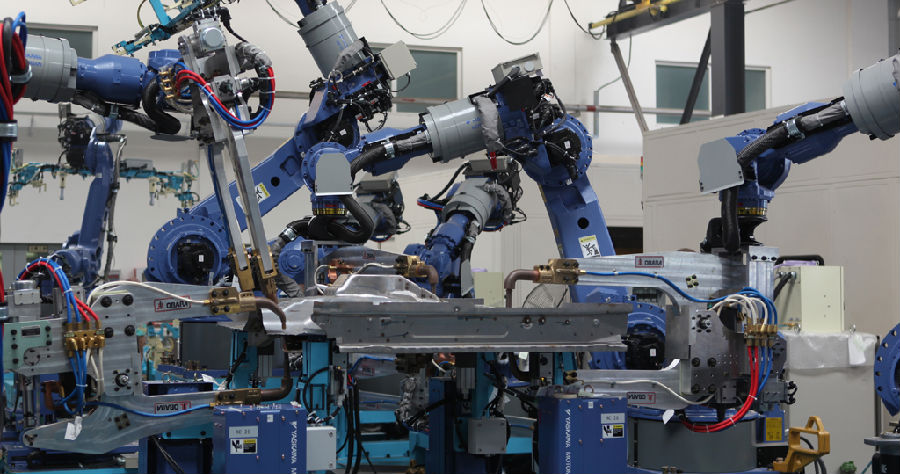

Robotic welding equipment

The LIMING planetary reducer is widely used in the robot welding industry to ensure the high precision, high torque, high response and other requirements of the robot in operation.

The planetary reducer used in the welding industry provides a stable power output for the robot to walk.

Welding robots have been widely used in automobile manufacturing, automobile lithium batteries and other welding.

It has been widely used in the production of automobile battery packs, automobile frames and chassis welding.

With this technique, the welding quality can be improved, and the movement time in short distances is greatly shortened.

The welding quality requirements of automotive battery parts are quite high, and their quality directly affects the safety performance of the car.

After the application of robot welding in the automobile industry, the appearance and internal quality of the welded parts are greatly improved, and the stability of the quality is ensured, the labor intensity is reduced, and the labor environment is improved.

With the rich experience and expertise accumulated in the field of welding robots, Liming reducer can provide integrated solutions in all aspects of movement and positioning.

Performance advantage

The LIMING planetary reducer has a high precision of 3 arc minutes, which makes the robot more precise and flexible.

The LIMING planetary reducer ensures high speed requirements and rapid acceleration and other working conditions, and is accurate. The low-wear design scheme ensures the reliability and service life of the application, and can run smoothly for a long time. Strong optimization efficiency, the transmission efficiency ratio is 98% Above, the power of the servo motor of the driven planetary reducer is also reduced.

The LIMING planetary reducer adopts precision equipment processing and advanced design concept of equal division structure. The planetary gears share the force on the planetary gears through the structure of equal weight sharing, and the gear noise is eliminated. Therefore, the noise caused by the change of load is eliminated. .

Because the design pursues the equal division structure of planetary gears, it can generate large torque, and at the same time, through the combination of standard gear units, various reduction ratios can be quickly obtained.

The LIMING planetary reducer can adapt to the application of various welding environmental conditions, and can operate normally even under extreme environmental conditions. It can also operate normally at temperatures as high as 70 degrees Celsius or -20 degrees Celsius, and has a higher protection level of IP68.

Reliability and extremely long service life, the accuracy of LIMING planetary reducer requires that the teeth of the internal gear, through correct meshing, will not be subjected to shearing force, and the service life will reach more than 20,000 hours.