Description

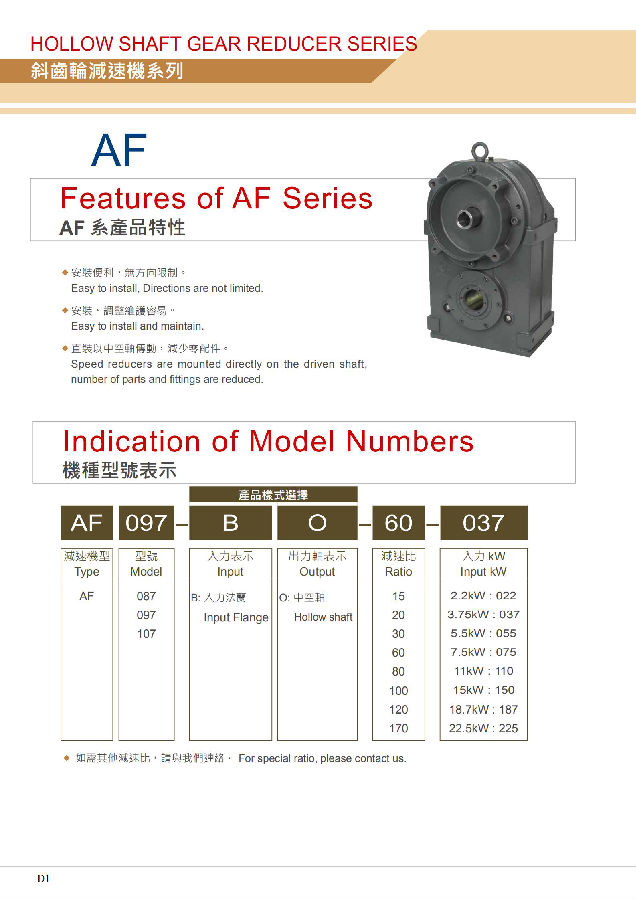

1. AF parallel shaft reducer: parallel output, compact structure, large transmission torque, stable operation, low noise and long life. Installation method: base installation, flange installation, torque arm installation. Reduction ratio: basic type two level 4.3-25.3, three

1. AF parallel shaft reducer: parallel output, compact structure, large transmission torque, stable operation, low noise and long life.

◆Installation method: base installation, flange installation, torque arm installation.

◆Deceleration ratio: basic type two level 4.3-25.3, three level 28.2-273, combined to 18509.

◆The rotation direction of the basic two-stage input and output is the same, and the three-stage is opposite; please consult when combining.

◆Output mode: hollow shaft output or solid shaft output.

◆Average efficiency: 96% of the second level, 94% of the third level, 85% of the average efficiency of F/CR

2. AS helical gear worm reducer: a helical gear and a worm gear are combined for integrated transmission to improve the torque and efficiency of the machine

This series of products have complete specifications, wide speed range, good versatility, and adapt to various installation methods

1. The surface of the machine body has the effect of heat dissipation, strong vibration absorption, low temperature rise and low noise.

2. The machine has good sealing performance and strong adaptability to the working environment, and can work continuously in harsh environments such as corrosion and humidity

3. The machine has high transmission accuracy and self-locking function, which is especially suitable for working in occasions with frequent starting

4. It can be connected with various types of reducers and equipped with various types of motor drives, and can be installed in the 90-degree transmission operating position

3. Bevel gear-helical gear reducer: the structure of the first-stage bevel gear plus the second-pole helical gear transmission.

1. Space saving, reliable and durable, high overload capacity, power up to 132KW;

2. Low energy consumption, superior performance, and the reducer efficiency is as high as 95% or more;

3. Low vibration, low noise and high energy saving;

4. Use high-quality forged steel material, rigid cast iron box, and the gear surface has undergone high frequency heat treatment;

5. After precision machining, to ensure shaft parallelism and positioning bearing requirements,

4. H helical gear reducer has the advantages of small size, light weight, high carrying capacity, high efficiency and long service life.

1. The coaxial helical gear reducer is manufactured in accordance with international technical requirements 2. It is space-saving, reliable and durable, with high overload capacity, and the power can reach 132KW; 3. Low energy consumption, superior performance, and the reducer efficiency is as high as 95% or more; 4. , Low vibration, low noise, high energy saving; 5. Use high-quality forged steel material, rigid cast iron box, the surface of the gear is high-frequency heat treated; 6. After precision processing, the shaft parallelism and positioning bearing requirements are ensured to form a helical gear transmission Assembly.