Description

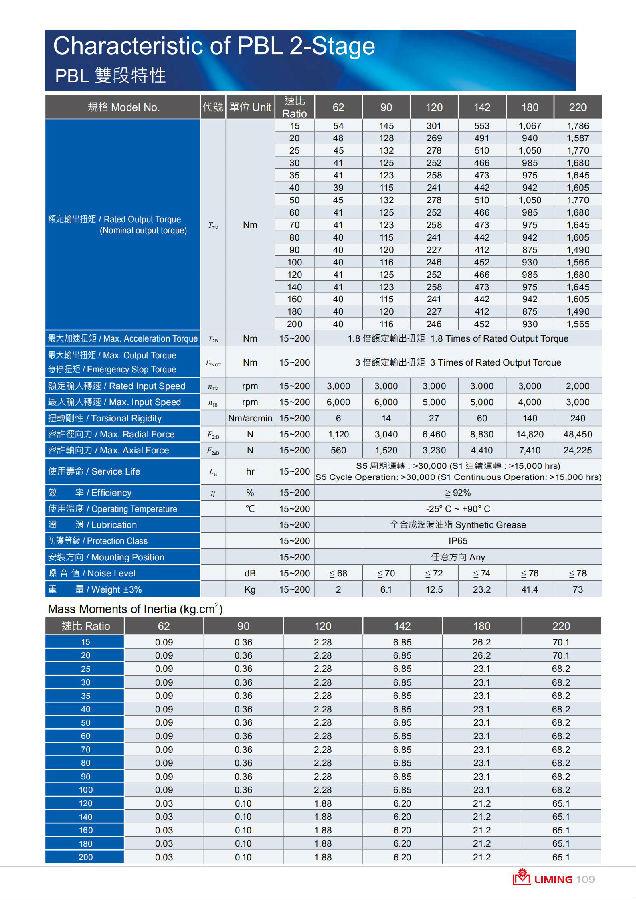

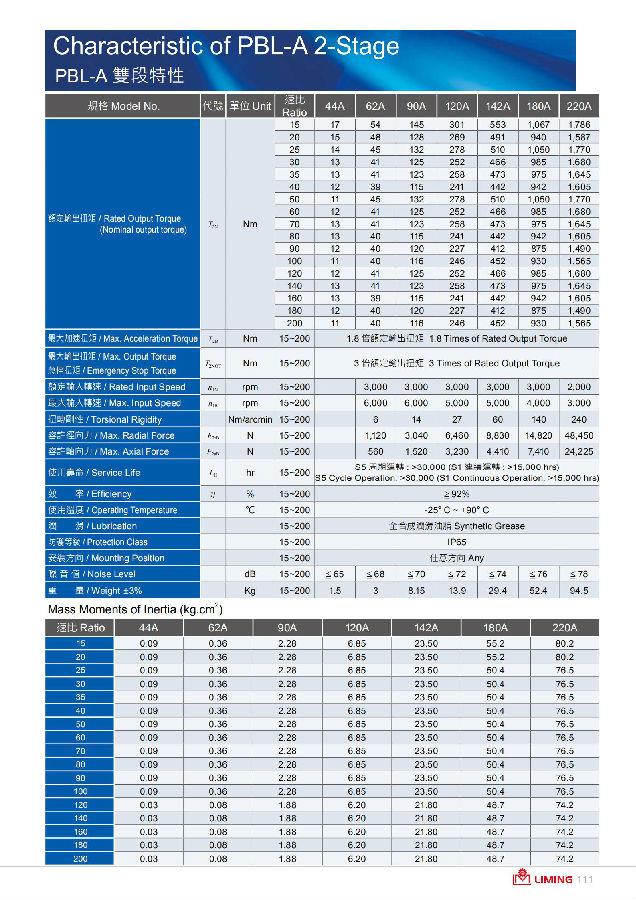

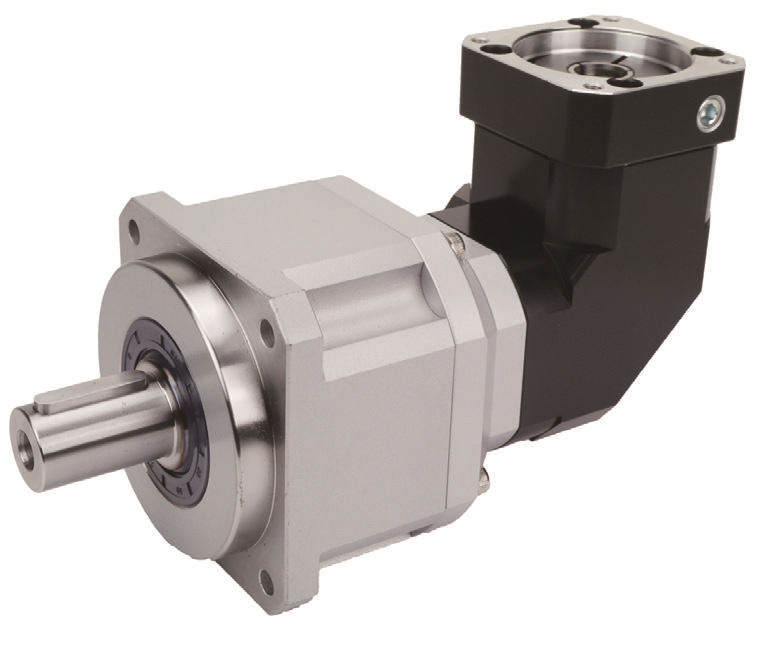

Liming reducer-PBL double-stage precision corner planetary reducer PBL series product advantages are silent: use high-precision helical gears to achieve smooth and quiet operation. High torque: higher torque than general spur gear planetary reducers. High efficiency: two-stage planetary reducer with

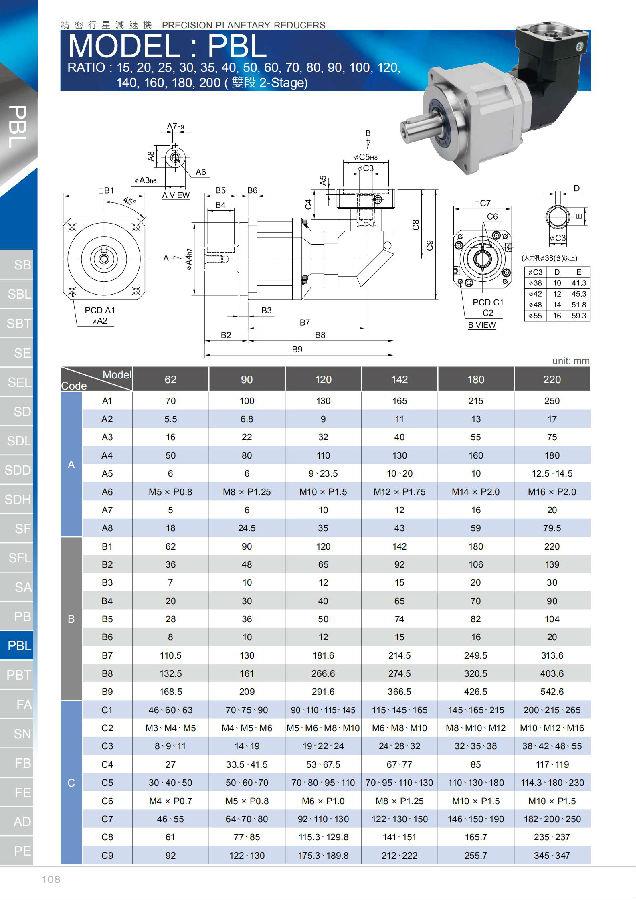

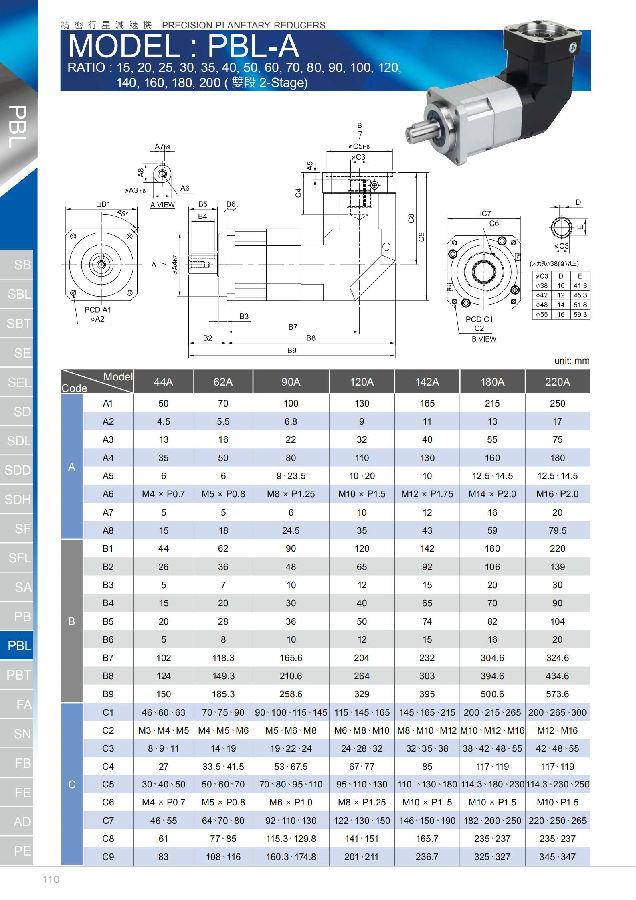

PBL double-stage corner planetary reducer

Liming reducer-PBL double-stage precision corner planetary reducer

Advantages of PBL series products

Quiet: Use high-precision helical gears to achieve smooth and quiet operation

High torque: higher torque than general spur gear planetary reducer.

High efficiency: The two-stage planetary reducer cooperates with high-precision bevel gears to increase the speed ratio of the reducer while ensuring that the efficiency is above 92%

Full needle roller bearing design

The transmission interface of the planetary gear adopts a full needle roller bearing without a retainer to increase the contact area to improve structural rigidity and service life.

Collet type connecting mechanism

The connection between the input end and the motor adopts a collet-type locking mechanism, and has undergone dynamic balance analysis to ensure the concentricity and balance of the interface at high input speeds, and the power transmission with zero backlash.

PBL double segment-product introduction

Frame number: 62#, 90#, 120#, 142#, 180#, 220# six kinds of frame numbers are optional

Reduction ratio: 15, 20, 25, 30, 35, 40, 50, 60, 70, 80, 90, 100, 120, 140, 160, 180, 200 17 kinds of reduction ratios are optional

Two-stage planetary reducer: adopts large and small series planets, and rotates the appropriate two-stage reducer under the condition that the size of the servo matching interface is matched.

Output shaft: You can choose whether to have a keyway or an optical shaft.

Accuracy: ≤15 arc minutes

Input speed: 3000-6000 rpm

Noise level: less than 73dB

Efficiency: up to 92% or more

Any installation: vertical, horizontal, horizontal, vertical