2021-06-04

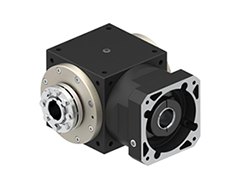

The hollow rotating platform is a new type of rotating load device. It combines high transmission power, high precision, high rigidity, and high cost performance. It combines the advantages of servo motors, cam dividers and DD motors to fully obtain a balance between these products.

Compared with other similar transmission positioning products, it can not only meet the direct load on the load one by one that the servo motor cannot do, but also compensate for the lack of the splitter's inability to locate any point of view. The positioning of any point of view is completed one by one. DD motor, but the cost is much lower than DD motor.

Features of hollow rotating platform

1. Hollow structure: The turntable of the hollow rotating platform is a hollow structure, and the servo motor is connected to the side to facilitate the installation of the air pipe and the wire in the fixture.

2. Arbitrary motor equipment: The hollow rotating platform can flexibly change the size of the interface through the method of customizing the flange and the input shaft hole, which is suitable for connecting any brand of servo motor and stepping motor.

3. Repeated positioning accuracy: The hollow rotating platform adopts helical gear deceleration method to increase the output torque. Some gears have a precision level of 2, which makes the hollow return of the hollow rotating platform extremely small, and the repeated positioning accuracy is below 10 arc seconds. (In order to ensure the accuracy, some parts are imported from Japan)

4. Direct connection: Same as splitter and DD motor, heavy objects can be placed directly on the platform for transmission.

5. Design: Taking into account the lateral force when the product is in use, the "interstitial roller bearing" is selected in the design of this product to better accept the lateral force load that occurs during the application. In order to ensure high precision, some parts are imported from Japan.

6. Processing: The main body of the hollow rotating platform is formed by dewaxing and is processed by precision level to ensure the accuracy of each part. The gear adopts the process of grinding after heat treatment. After processing, it can reach the level 2 gear accuracy, and its surface hardness can reach HRC52. After the product is assembled, another grinding process will be carried out to ensure the parallelism and perpendicularity of each part.

7. Inspection: After the assembling of each product is completed, the gear backlash and repeated positioning accuracy will be inspected by viewpoint analysis to ensure the entire process inspection of the product, and no random inspection or missed inspection will be carried out.