Description

The CE series aluminum alloy worm gear reducer is a new generation product developed on the basis of the original NE series of our factory. The body is formed by high-quality aluminum alloy die-casting, which is small in size, fast in heat dissipation, and the surface is treated with a film to prevent rust. Beautiful and durable. The worm is made of tongs alloy steel (SCM415), after carburizing heat treatment and grinding, the transmission is stable, the noise is small, the output torque is large, and it can be adapted to all-round installation.

Aluminum alloy worm gear

CE series features

The CE series aluminum alloy worm gear reducer is a new generation product developed on the basis of the original NE series of our factory. The body is formed by high-quality aluminum alloy die-casting, which is small in size, fast in heat dissipation, and the surface is treated with a film to prevent rust. Beautiful and durable. The worm is made of tongs alloy steel (SCM415), after carburizing heat treatment and grinding, the transmission is stable, the noise is small, the output torque is large, and it can be adapted to all-round installation.

Use factor fs

The driven effect of the driven mechanism on the reducer is measured by using the coefficient fs. The utilization factor is determined according to the daily operating time and starting frequency Z. The three load classifications depend on the inertial acceleration coefficient. The actual application coefficient can be read in the figure below. The use coefficient selected according to this table must be less than or equal to the use coefficient provided in the performance parameter table.

Load type:

Light-load screw conveyor, fan, equipment line, conveyor belt, small agitator, elevator, cleaning machine, screening program, control drive.

Winches, woodworking machine feeders, cargo cranes, balancers, threading machines, medium mixers, heavy conveyor belts, winches, sliding gates, scrapers, packaging machinery, concrete mixers, crane drives, iron beds, gears Pump.

CE series aluminum alloy worm gear reducer

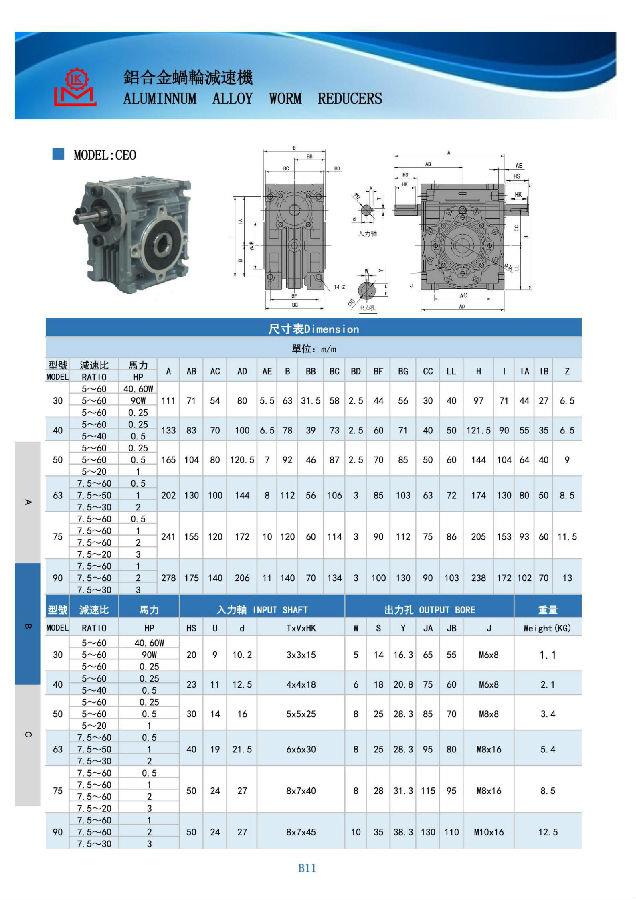

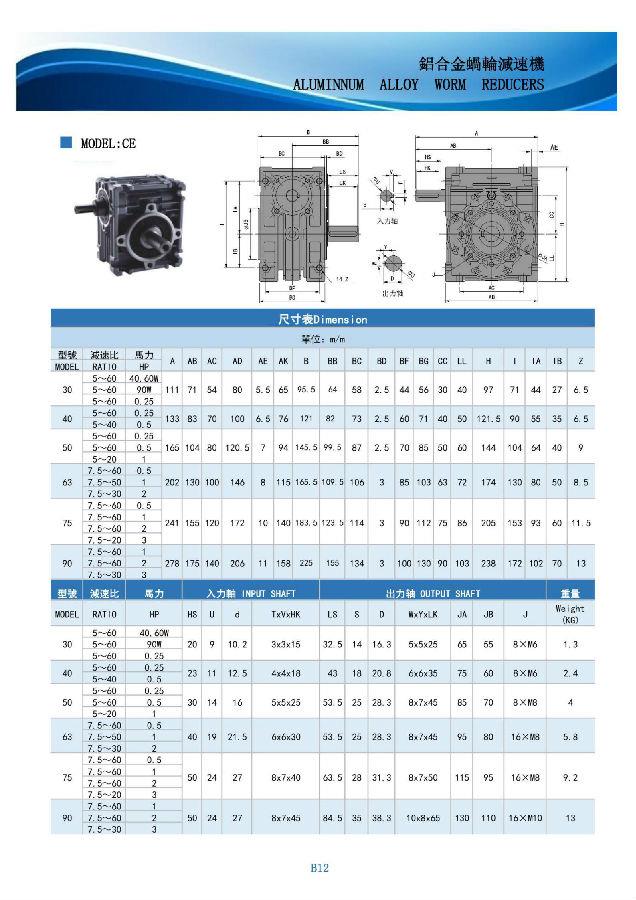

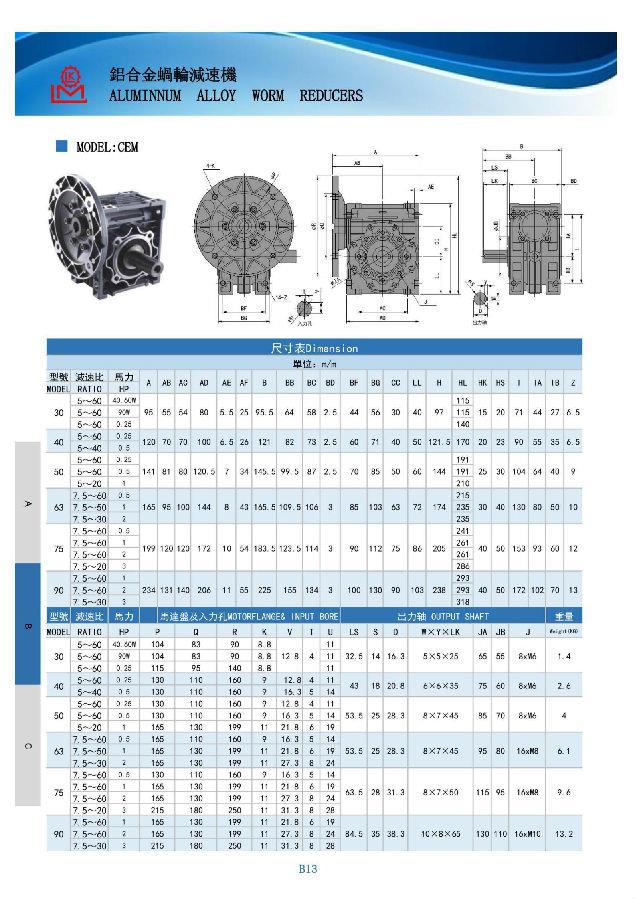

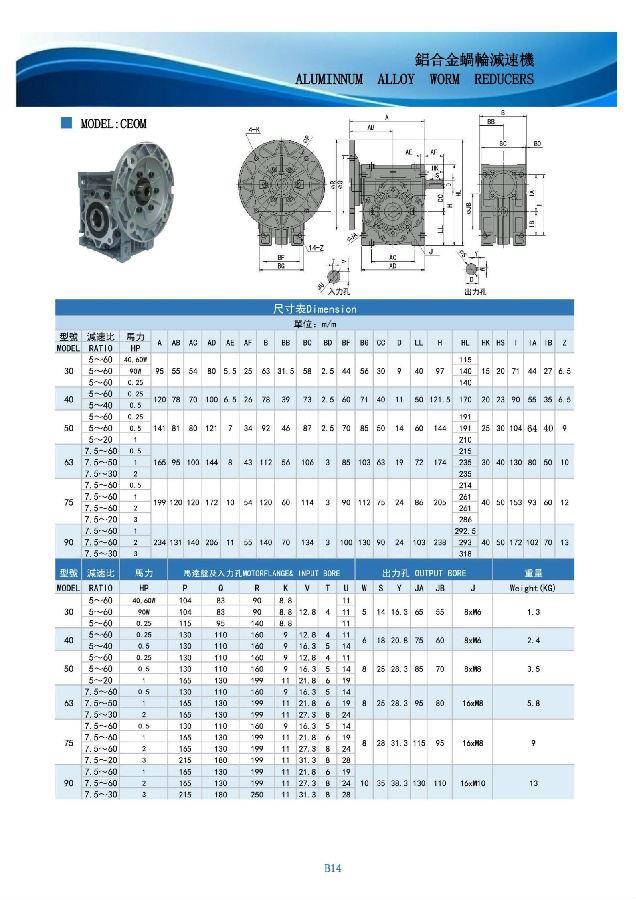

Models: 30, 40, 50, 63, 75, 90

Reduction ratio: 5, 7.5, 10, 15, 20, 25, 30, 40, 50, 60

Axial representation:

Right axis (the input axis faces itself, the output axis is on the right)

L: Left axis (the input axis faces itself, the output axis is on the left)

V: Single input shaft and double output shaft

W: Double input shaft and single output shaft

WV: Double input shaft and double output shaft

S: Special shaft (please specify when ordering or the picture attached)

Rotation direction: The worm is designed to use right-handed teeth, so when the input shaft rotates in a clockwise direction, the output shaft rotates in a counterclockwise direction. If you need a special direction of rotation, please specify.